Modern Spartan Systems

Accuracy Oil Review

A little while ago, Modern Spartan Systems shot me an email

about their products. Before speaking on the phone, I did my due diligence and

dug into them. I'll admit, some of the claims they were making threw up some

red flags for me, mainly the claim that it tightens shot groups. I didn't see

any really convincing test data to properly back up the claim. I kept digging

around and watched their videos. The closest thing to a scientific test I saw

was their video of the Timken Bearing Test. The test was pretty impressive, but

I was still a bit wary of the accuracy claims. So, when I finally spoke to them

on the phone, I agreed to properly test the claim in an upcoming Basic Tactical

Rifle course. The Basic Tactical Rifle course I teach was a great fit for the

testing, because we spend time on the chronograph and grouping- so measuring

results would be easy.

I'm not a bench

rest shooter, and I did not feel in our application, that measuring shot group

size would be an honest metric. The shot group size would naturally decrease

throughout the course as we worked on skills. Grouping size contained too many

non-deterministic variables to reliably test. For this reason, I focused on

provable data. While more consistent velocity alone doesn't necessarily mean

better accuracy, consistent velocity is a key deterministic variable of

external ballistics and does directly translate to bullet (gravity) drop when

combined with other deterministic variables. Just wanted to throw that in

there before the peanut gallery chimes in.

Setup

I asked all the students to clean their bores before they

showed up so we could get clean results. I used an Oehler 35p chronograph. The

Oehler 35p is an industry standard chronograph, which has 2 stop screen

channels and compared velocities between the two to ensure there is not an

error.

Day 1:

We shot a

string through the Oehler, without the oil, to establish velocity numbers and

select a good zero distance on each rifle. We continued our training for the

rest of the day without issues (we did find one rifle's T-1 sight had the worst

parallax movement I have ever seen past 50yds in a red dot sight, but that is

another story) Students were told to clean their bores again that night and

show up clean the next day.

Day 2:

Early that

morning I was notified we were -1 student as one got a sectional cleaning rod

and multiple patches stuck. (Stop using Otis origami patches, use one square in

your caliber and pull, don't push from chamber to barrel. If it takes more

effort than you can exert without spilling your beer (don't judge- you know you

do this), stop and lightly tap it out the way it came with a mallet).

On arrival,

we followed the initial treatment protocol.

1.

We ran a patch wet with Accuracy Oil through

each bore a few times.

2.

We then fired a 10 round group @ 100yds.

3.

After checking targets, we re-treated all

barrels, running a patch wet with Accuracy oil through each bore a few times.

4.

We then fired a 10 round group @ 100yds.

5.

After checking targets, we re-treated all

barrels, running a patch wet with Accuracy oil through each bore a few times.

6.

We then fired a 10 round group @ 100yds.

7.

After checking targets, we re-treated all

barrels, running a patch wet with Accuracy oil through each bore a few times.

8.

We then fired a 10 round group @ 100yds.

9.

After checking targets, we re-treated all

barrels, running a patch wet with Accuracy oil through each bore a few times.

10. We

then fired a final 10 round group @ 100yds.

11. All

rifles were then chronographed.

To

summarize- we cleaned, then treated, then fired 5 x 10rd groups, treating

between each group, then recorded data.

Results

Everyone in

the class was pretty amazed by the results. Every shooter gained velocity, decreased

their standard deviation, and drastically decreased their extreme velocity

spread.

Definitions

Just in

case you may not be familiar with chronograph data or it's meaning, let me

define the terms as the Oehler 35p captures them:

Highest

Velocity- simply, the fastest value collected.

Lowest

Velocity- simply, the lowest value collected.

Extreme

Velocity Spread- this is the simple difference between the highest and lowest

value collected.

Mean

Velocity- This is the average of the data collected.

Standard

Deviation- this value describes the uniformity. The value is represented like

this: +/- 18fps. This value means that, based on the data collected, at least

2/3rd of the rounds you fire will be within 18fps of the average

velocity (the actual math behind calculating this will make your head hurt,

just trust me here).

THE HARD NUMBERS

Now, Let's have a look at the equipment used. Below is a

chart of the rifles and the ammo they used, each ammo type was from the same

lot, respectively (I apologize in advance, I'm not a spreadsheet pro- deal with

the lack of aesthetics):

I liked

that we had a good spread of brands and ammo, so we could rule out values only

being consistent to one type or brand.

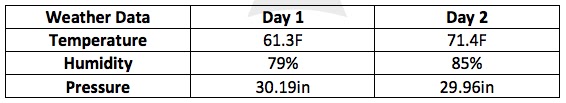

Here is the

weather condition from the two days at the time of measurement for each day. No

huge differences that would drastically alter the results:

The Clean Bore column represents the data from Day 1,

which was untreated with the Accuracy Oil, the Treated Bore is from Day 2

after the treatment steps were finished.

-

We can see right away that the Highest Velocity

and the Lowest Velocity both increased.

-

We also see that the Extreme spread decreased,

which is great.

-

The Mean Velocity increased.

-

The Standard Deviation decreased.

All of

these numbers are improvements, indicating the Accuracy Oil works. -4 on a

standard deviation may not sound like much, but it is.

Now that we've broken down the results, let's

look at the other 4 rifles:

Yep, you're seeing that right and we were just as impressed

when we saw the results print out. Every single rifle registered improvements

across the board- regardless of rifle manufacturer and ammo type.

Some rifles

recorded results that were FAR more drastic than others, but that could also be

explained by barrel condition. The manufacturer claims the oil bonds with the

inside of the barrel, creating a smoother surface- decreasing friction. So, if

that is correct, then a barrel with more imperfections could show more

improvements than a barrel in better condition. The results on Gun #3 are an

example of this.

Now, let's see an average of all the guns:

Fairly impressive results, but how does that translate to

accuracy? As I stated before, velocity data is one of the key deterministic

variables of external ballistics. They will compound with other variables to

produce your shot group. Many shooters in the industry blow this off, because

they don't think it matters much. But, then they spent $1,200 on a sub MOA

rifle, and another $600-$1,200 on quality optics, because it doesn't matter,

right? EVERYTHING MATTERS. Remember, change in drop from velocity will compound

with the accuracy of the barrel, consistency of your sight placement,

marksmanship fundamentals, and other external ballistics variables to produce

your shot group. Don't let your equipment add unnecessarily to the error you

will induce to your shot group the second you wrap your meat-grippers around

that rifle.

Here are some more aesthetically pleasing charts

of the average changes in FPS and %:

Here is a chart, referencing Gun #2 and

translating the velocities to inches of drop at 300yds.

What this is showing is that this shooter's lowest point of

impact raised by 1.3" and his average point of impact by 1". This means that

his rifle is now shooting flatter out to 300yds. If you customize your zero

distance, that 1.3" gain can help a lot in balancing how high your round is

above your line of sight between 100-200yds and how low it is at 300yds.

The Extreme

Velocity Spread section shows the difference, in inches, of the high and low

velocity rounds. This translates to a difference in shot group size (yes, other

external ballistic factors will affect this as well). So, untreated we had a

1.8" size and treated we had a 1.2" size- a change of -.6" or 33.33%.

Gun #2 had

fairly average results in our group, here's Gun #3:

So, Gun #3 had its lowest drop pushed up 1.7" and its

average drop pushed up .9". The big story with this rifle is the extreme

spread. Before treatment, the velocities indicated a drop spread of 2.9", after

treatment it shrunk to 1". I would take a decrease in shot group size due to drop

spread of 1.9" any day.

CONCLUSIONS

The product

works with regards to its muzzle velocity claims, get this stuff in your barrel

now. I still want to see better and more

extensive testing. If this oil is decreasing friction to this extent, we should

see a very noticeable increase in barrel life- I want to see numbers on that. I'd

like to see how many rounds this treatment lasts, and see a treatment schedule

recommended. I would like to see some testing on how it performs in the upper

receiver beyond "it feels great". Until that happens, I can't recommend that

guys who pull triggers doing jobs where their lives depend on it put this on

their bolt. But, I will absolutely

recommend getting this oil in your barrel today.

On a side

note, before this course I used their Carbon Destroyer on my bolt. I had a

decent amount of carbon plating on it. I let the product soak in it while I

cleaned my bore. Almost all the carbon came off with an all-purpose brush.

Sorry I didn't get any pictures of the before and after, but give it a try

yourself.